Alejandra Jolodosky, Alan Bolind, and Massimiliano Fratoni

The goal of this work is improved safety and performance for fusion energy. Lithium is often the preferred choice as breeder and coolant in fusion blankets as it offers excellent heat transfer and corrosion properties and, most importantly, has a very high tritium solubility that results in very low levels of tritium permeation throughout the facility infrastructure. However, lithium metal vigorously reacts with air and water, exacerbating plant safety concerns. Consequently, Lawrence Livermore National Laboratory (LLNL) is attempting to develop a lithium-based alloy—most likely a ternary alloy—that maintains the beneficial properties of lithium (e.g. high tritium breeding and solubility) while reducing overall flammability concerns for use in the blanket of the Inertial Fusion Energy (IFE) power plant.

The goal of this work is improved safety and performance for fusion energy. Lithium is often the preferred choice as breeder and coolant in fusion blankets as it offers excellent heat transfer and corrosion properties and, most importantly, has a very high tritium solubility that results in very low levels of tritium permeation throughout the facility infrastructure. However, lithium metal vigorously reacts with air and water, exacerbating plant safety concerns. Consequently, Lawrence Livermore National Laboratory (LLNL) is attempting to develop a lithium-based alloy—most likely a ternary alloy—that maintains the beneficial properties of lithium (e.g. high tritium breeding and solubility) while reducing overall flammability concerns for use in the blanket of the Inertial Fusion Energy (IFE) power plant.

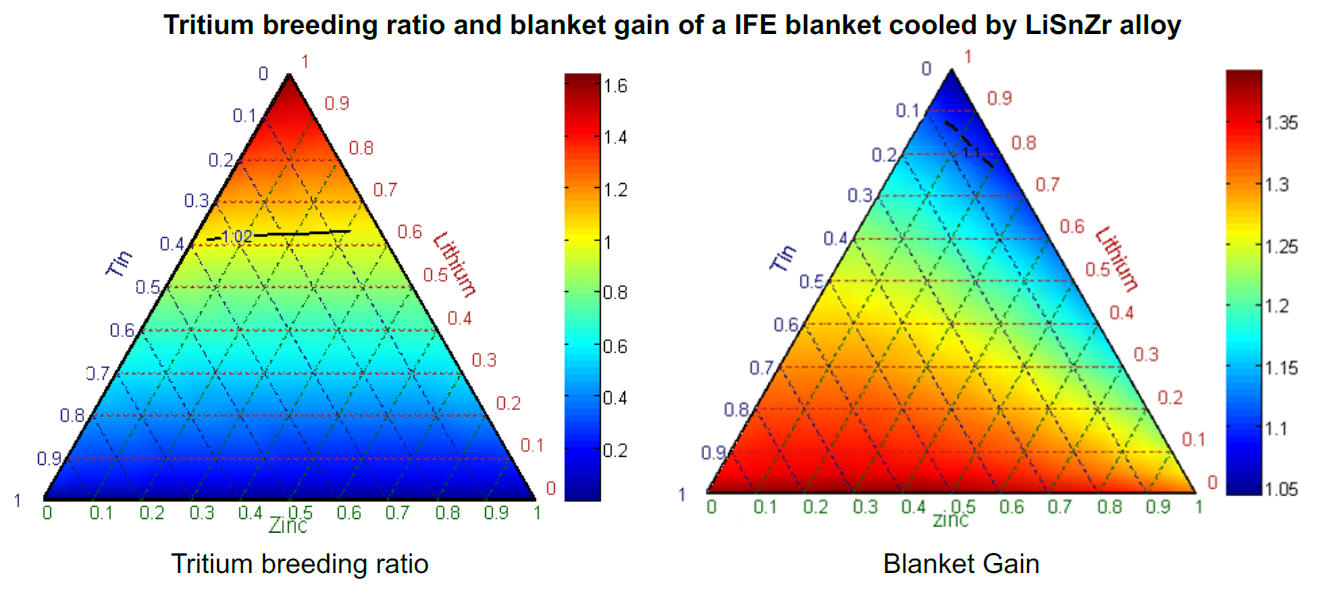

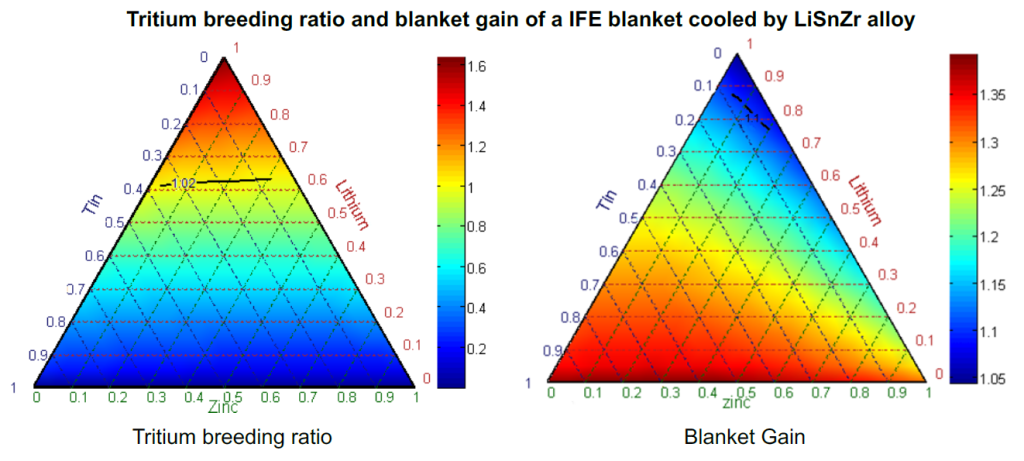

The IFE power plant being studied employs inertial confinement fusion (ICF) through the use of lasers aimed at an indirect-driven target composed of deuterium-tritium fuel. The fusion driver/target design implements the same physics as the National Ignition Facility (NIF). The IFE power plant uses lithium in both the primary coolant and blanket; therefore, lithium-related hazards are of primary concern. Although reducing chemical reactivity is the primary motivation for the development of new lithium alloys, the successful candidates will have to guarantee acceptable performance in all their functions. Our focus is to evaluate the neutronics performance of a large number of lithium-based alloys in the blanket of the IFE engine. In particular, parameters determining alloy selection are the tritium breeding ratio (TBR) and energy multiplication factor (EMF). Activation analysis is performed on the selected alloys to assess specific safety and environmental properties, including evaluation of decay heat, contact dose rate, accident dose, and waste disposal rating.

Neutronic analysis found that the best performing alloys (higher TBR and higher EMF) combine elements that exhibit low absorption cross sections and high q-values, such as tin, barium, strontium, or zinc, with elements with high neutron multiplying cross sections, like lead or bismuth. A large number of alloys (e.g. LiPbZn and LiSnZn) met TBR constraints greater than or equal to 1.05 and an EMF constrain greater than or equal to 1.1 for a wide range of lithium concentrations. When the EMF constraint was increased to 1.2, the additional power demand was too high for alloys not containing tin. Additionally, it was found that when an alloy already contains a high amount of lithium (greater than 50%), doubling the 6Li content from 7.5% to 15% increases the TBR by 13%. After a certain percent of enriched 6Li, the lack of tritium and additional neutrons produced from 7Li(n,n’T) reactions end up reducing the TBR. At lower total lithium concentrations (<50%), the TBR will continue to increase to higher 6Li enrichments since the 7Li(n,n’T) reactions will not be as significant.

Activation calculations were performed for a series of elements that exhibited good TBR and EMF properties. This analysis revealed bismuth as a poor choice as it performed worst for all of the criteria evaluated. Alloys containing zinc and tin also showed some of the highest decay heats, contact dose rates, and accident doses. Most of the alloys examined can be stored in dry containers at an estimated one year after shutdown. Additionally, if necessary, the entire volume of the blanket for every alloy except LiPbBa and LiBaBi could be remotely handled. Accident doses were high in alloys containing zinc, copper, or gallium, but were not high enough to pose a major safety concern. With the exception of LiBaBi, activation analysis demonstrated that all the alloys could be used as blankets of the IFE reactor without posing major environmental or safety concerns.

Future neutronics work will focus on the optimization of lithium-ternary alloy concentrations for a given TBR and EMF.